How to Choose the Right Industrial HVAC Units for Your Business Needs?

Choosing the right industrial HVAC units for your business is crucial. The efficiency of these systems can directly impact operational costs and employee comfort. According to a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), up to 40% of energy bills are attributed to heating and cooling systems. A well-chosen system not only reduces energy waste but also helps maintain air quality.

Expert in the field, Dr. Jane Evans, emphasizes, "Selecting the right industrial HVAC units can save businesses thousands annually." This underscores the importance of careful selection. However, many businesses overlook the nuances of their specific needs. Each facility has its unique demands based on size, layout, and industry requirements.

It’s not just about size or capability; it’s about matching functionality to purpose. Businesses often struggle to pinpoint their exact needs. This can lead to overpaying for features they don’t use or underestimating necessary capabilities. Therefore, taking the time to assess your requirements can lead to better long-term satisfaction with your industrial HVAC units.

Factors to Consider When Selecting Industrial HVAC Units

When selecting industrial HVAC units, various factors come into play. The size of your facility significantly influences your decision. According to a report by ASHRAE, improperly sized units can lead to energy inefficiency by up to 30%. Understanding the square footage and ceiling height of your space is crucial. A precise calculation ensures optimal air distribution and comfort.

Another key factor is energy efficiency. The energy efficiency ratio (EER) and seasonal energy efficiency ratio (SEER) are critical metrics. Units with higher ratings can reduce operational costs significantly. Industry reports suggest that a unit with a 10 percent increase in efficiency can lead to energy savings of nearly $300 annually in a medium-sized facility. Yet, many businesses overlook these metrics, leading to poor long-term investments.

Consider the maintenance demands of the HVAC systems as well. Some units require more frequent servicing and are challenging to maintain. This can lead to increased downtime and unexpected costs. A bit of reflection on future maintenance needs may save businesses from headaches down the road. Balancing initial costs with long-term performance and upkeep is essential in the decision-making process.

Energy Efficiency Ratings of Industrial HVAC Units

This bar chart displays the energy efficiency ratings (SEER) of various industrial HVAC units. Higher SEER ratings indicate better energy efficiency, which can lead to reduced operating costs and a lower environmental impact.

Understanding Different Types of Industrial HVAC Systems

When selecting industrial HVAC systems, understanding the types available is crucial. There are several main categories: unitary systems, split systems, and centralized systems. According to a recent report from the U.S. Department of Energy, about 40% of energy in commercial buildings is used for heating and cooling. This underscores the importance of making informed choices.

Unitary systems consist of a single package that handles both heating and cooling. They are often ideal for smaller spaces. Split systems, on the other hand, separate the indoor and outdoor units. This flexibility allows for different configurations, which could be beneficial for larger facilities. Centralized systems offer comprehensive control but might demand higher initial investments and ongoing maintenance.

It's essential to reflect on the specific needs of your facility. Are you in a humid climate? You might prioritize dehumidification capabilities. Is energy efficiency a significant concern? Look into systems with high SEER ratings. Reports indicate that a 10% increase in efficiency can lead to a 20% reduction in energy costs, making it vital to weigh these factors carefully. Ignoring the unique demands of your business can lead to oversizing or undersizing HVAC units, causing wasted energy and potential discomfort for employees.

Assessing the Size Requirements for Your Facility

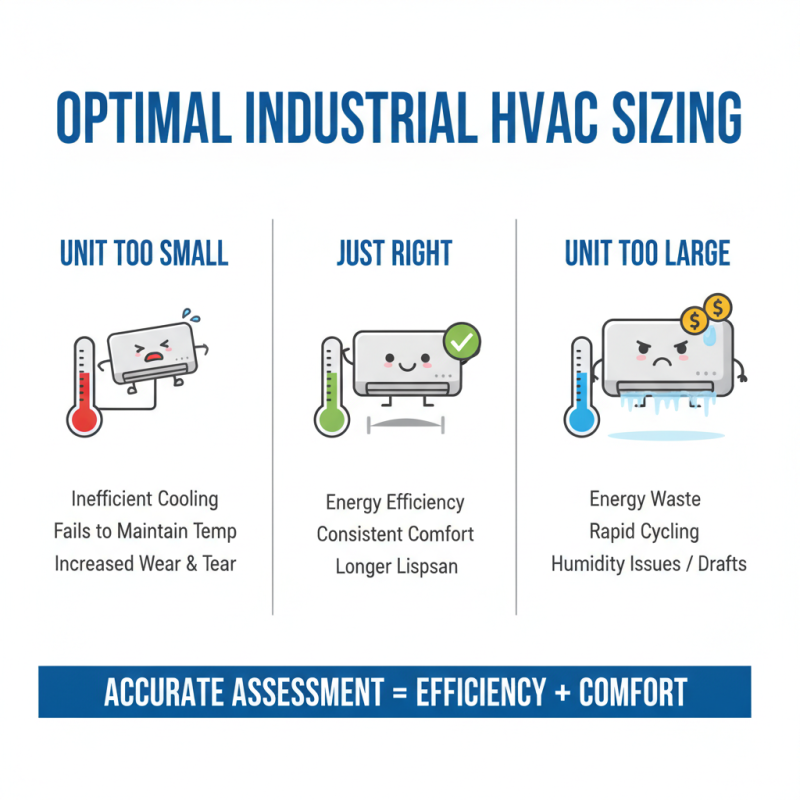

When choosing industrial HVAC units, size is crucial. A system too small will struggle to maintain temperatures. Conversely, a unit that is too large can waste energy and create uncomfortable conditions. Assessing your facility's size accurately ensures efficiency and comfort.

Start by calculating the total airflow needed. This involves measuring the square footage of your space. Take into account the ceiling height and layout as well. Different areas may have varying cooling or heating needs. For example, a warehouse may require a different approach than an office space. Assessing insulation and window sizes also impacts your decision.

Don't overlook future growth. Your business might expand in a few years. Consider this when choosing your HVAC system. You may want to adjust the capacity for expected changes. While it’s essential to stick to current needs, planning ahead is wise. Balancing present and future demands is not always straightforward. It's a challenge that requires careful thought and flexibility.

Evaluating Energy Efficiency and Operating Costs

When evaluating energy efficiency and operating costs for industrial HVAC units, it's critical to consider several factors. Energy efficiency ratings can help, but they don't tell the whole story. Look into the specific features of each unit. Some systems may have better ratings but are more costly to maintain. It's common for businesses to rush this decision, which can lead to unexpected expenses later on.

Operating costs involve more than just energy consumption. Routine maintenance plays a significant role. Neglecting this can double your costs over time. Choose units that allow for easy access to components for servicing. Also, consider the environmental impact. Sometimes, the cheapest option initially can lead to higher costs in the long run.

Another aspect to ponder is the size of the system. An oversized unit may seem efficient at first, but it can lead to frequent cycling, increasing wear and tear. Balancing size and energy efficiency requires careful analysis. Don't forget to compare long-term operational costs against initial purchase prices. It's an easy mistake to prioritize upfront savings only to regret it later.

Importance of Professional Installation and Maintenance Services

When it comes to industrial HVAC systems, professional installation is crucial. A report from the Energy Information Administration highlights that improperly installed systems can reduce efficiency by up to 30%. This inefficiency can lead to increased operational costs and energy waste. Proper installation by trained technicians ensures that all components function harmoniously. It minimizes the risk of breakdowns and ensures longevity.

Routine maintenance is just as vital. According to a study by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), regular maintenance can extend system life by 25%. Failing to keep up with maintenance can lead to costly repairs and replacements. Many businesses overlook this, thinking their systems will operate indefinitely.

However, neglecting maintenance can result in poor air quality and system failures. Filters should be inspected monthly. Ductwork can accumulate dust and debris, which hinders efficiency. Remember, a neglected HVAC system reflects poorly on your business. Quality service is non-negotiable for optimal performance.

Related Posts

-

2025 Top Industrial HVAC Units: Enhance Efficiency with 15% Energy Savings

-

How to Choose the Right HVAC System for Your Business Efficiency and Savings

-

Top 10 New HVAC Units for Efficient Home Heating and Cooling

-

10 Best Industrial HVAC Systems for Optimal Energy Efficiency in 2023

-

Understanding the Essential Parts of HVAC System for Improved Home Efficiency in 2025

-

Top 10 Essential Parts of HVAC System You Need to Know